Weathering steel, best known under the initial trademark name COR-TEN® (‘Corten’) steel, is a high-strength low-alloy steel that was initially developed for increased corrosion resistance. The original COR-TEN steel (trademarked by U.S. Steel) was designated as ASTM A-242 (“Cor-ten A”), although its application is not currently recommended by the U.S. Steel company. The modern and current recommended grades of Cor-ten steel that are readily available are designated by the ASTM (international standards group) as HSLA A588/A588M (plate) and HSLA A606-04 (sheet). We use the names Cor-ten and weathering steel interchangeably due to Cor-ten’s widespread recognition.

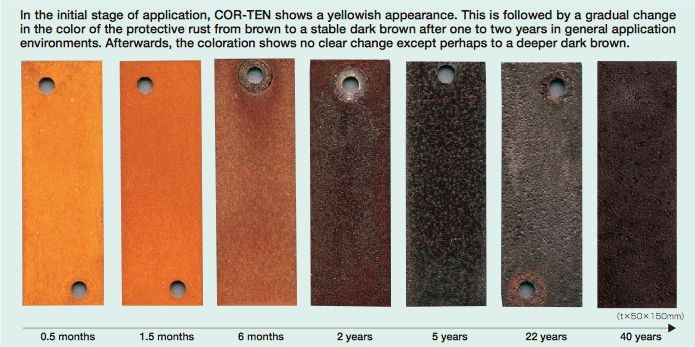

These grades of weathering steel exhibit superior corrosion resistance over regular carbon steel as a result of the development of a protective oxide film on the surface of the steel. The layer protecting the surface is dynamic and continuously regenerates when subjected to the influences of the weather and ambient environment. Even though weathering steel is not completely rustproof, it possesses a high corrosion resistance once aged (approximately twice that of carbon steels). The burden for many applications of weathering steel is the protective rust layer is usually naturally formed only after 6-10 years of active natural exposure to the elements (depending on degree of exposure). Until the protective ability of the rust layer emerges, the corrosion rate is not considerably low and the initial flash rusting contaminates its own surface and that of other nearby surfaces.

These grades of weathering steel exhibit superior corrosion resistance over regular carbon steel as a result of the development of a protective oxide film on the surface of the steel. The layer protecting the surface is dynamic and continuously regenerates when subjected to the influences of the weather and ambient environment. Even though weathering steel is not completely rustproof, it possesses a high corrosion resistance once aged (approximately twice that of carbon steels). The burden for many applications of weathering steel is the protective rust layer is usually naturally formed only after 6-10 years of active natural exposure to the elements (depending on degree of exposure). Until the protective ability of the rust layer emerges, the corrosion rate is not considerably low and the initial flash rusting contaminates its own surface and that of other nearby surfaces.

WHAT MAKES WEATHERING STEEL PROTECTIVE?

The developed oxide structure that establishes on the surface of weathering steel generally consists of two layers; an outer and inner layer. The inner layer is mainly composed of densely packed fine-particles which are adhered to the steel surface (adherent rust), while the outer layer is continually evolving and re-developing new rust products that are typically non-adherent (non-adherent rust). Over time, the outer layer becomes less and less active, with the inner layer becoming more prominent.  This is what gives weathering steel (or Cor-ten) its unique appearance and texture. As the outer rust products (lepidocrocite, magnetite,etc.) grow in size and weather away, the inner protective products (mainly goethite) continue to form and become more densely packed. This densely packed inner layer, mainly consisting of nano-phase goethite (>15 nm in size), is where the protective qualities of weathering steel exist.

This is what gives weathering steel (or Cor-ten) its unique appearance and texture. As the outer rust products (lepidocrocite, magnetite,etc.) grow in size and weather away, the inner protective products (mainly goethite) continue to form and become more densely packed. This densely packed inner layer, mainly consisting of nano-phase goethite (>15 nm in size), is where the protective qualities of weathering steel exist.

The rust products in this inner layer become so densely packed that water molecules are unable to pass through and oxidize the inner steel substrate. This is what gives weathering steel it’s skin-like texture and feel. Most carbon steels, when oxidizing, create rust products that are so large they separate from the steel substrate and flake off. The oxide layer on weathering steel, once well-developed, has a smooth surface texture that feels as though there is a protective coating present. This is where the value in the use of weathering steel exists. This has been the focus of Distressed Metal’s research and is where our expertise is unmatched by other companies in the business. Without the ability for the protective layer to develop, weathering steel performs just like carbon steel.

Our approach is to manage the initiation and growth of the oxide layer at the beginning stages, in order to develop a patina which has beautiful, resonant tones along with a reduction of loose rust particles. Our pre-weathering process allows you to bypass the initial oxidation periods on-site, in order to mitigate the amount of bleeding and change that typically occurs within the first 6-24 months (if applied raw).

DOES WEATHERING STEEL STOP RUSTING?

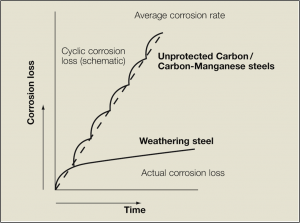

Not completely. Weathering steel, if applied appropriately, significantly reduces the amount of corrosion, yet never completely stops. As you can see in the diagram, once the protective layer is developed, the corrosion loss is reduced substantially. Our approach is to bring the initial corrosion under control and lay the groundwork for the protective oxide layer to ‘turn the corner’ (with reference to the graph). Once a rust layer has been sufficiently established, the corrosion occurs within the oxide layer, further developing the patina instead of mainly releasing the loose rust products. With a protective oxide coating in place, weathering steel’s durability and longevity is equivalent and can exceed that of a painted building product.

Not completely. Weathering steel, if applied appropriately, significantly reduces the amount of corrosion, yet never completely stops. As you can see in the diagram, once the protective layer is developed, the corrosion loss is reduced substantially. Our approach is to bring the initial corrosion under control and lay the groundwork for the protective oxide layer to ‘turn the corner’ (with reference to the graph). Once a rust layer has been sufficiently established, the corrosion occurs within the oxide layer, further developing the patina instead of mainly releasing the loose rust products. With a protective oxide coating in place, weathering steel’s durability and longevity is equivalent and can exceed that of a painted building product.

APPLICATION

Weathering steel can be utilized as an element in an exterior rain screen facade, within an interior panel system with a high performance clear top coat (or raw), as signage, or in a specially fabricated structure such as a blade wall or artistic piece.

How can weathering steel be applied in your future project?